Welcome:GZTECH

Welcome:GZTECH

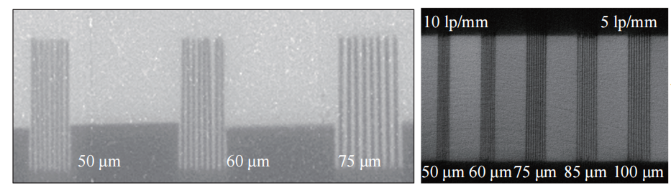

As one of the most advanced non-destructive testing methods, high-energy CT (Computed Tomography) has important application value in the precision testing of large components and large equipment in industries such as national defense, aerospace, nuclear power, and high-speed rail transportation. The spatial resolution of conventional high-energy CT systems is limited to less than 3.5 lp/mm, which hinders its further application in high-end equipment.

The "Jingwei" system developed by the China Academy of Engineering Physics shortens the detection sampling time to 15-30 minutes, and improves the imaging spatial resolution by 2-3 times compared with the world's highest spatial resolution CoLoSSIS system, and shortens the minimum scanning time to 1/5-1/10.

Figure 1 "Jingwei" high spatial resolution imaging results

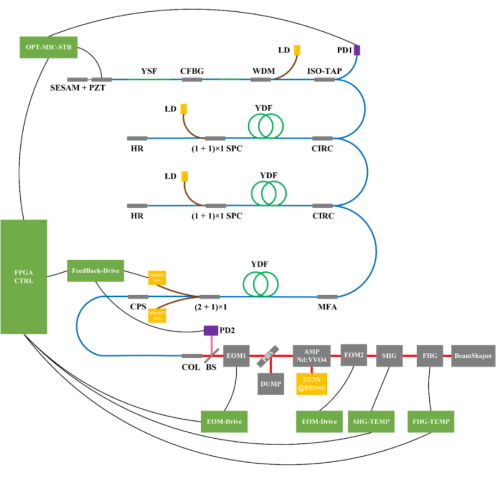

The improvement of the spatial resolution of high-energy CT first requires a high-quality electron source, that is, a high-brightness electron beam with lower emittance and lower energy dispersion under a certain current intensity. GZTECH took one year to develop and deliver a low-noise 266nm picosecond laser. As a key subsystem for the excitation of the photocathode to generate electron beam clusters in the "Jingwei" system, it generates high-quality and low-time jitter electron beam clusters for the subsequent gas pedals, effectively improving the detection efficiency and resolution of the system.

Figure 2 Schematic diagram of the optical path of a low-noise 266 nm picosecond laser

Based on the principle of saturable absorber (SESAM) mode-locking, through the precise design of cavity length and control of dispersion, 178.5MHz repetition frequency and pulse output of about 12ps are realized. SESAM is fixed on the piezoelectric ceramics, which can precisely control the cavity length to suppress the influence of environmental noise on the cavity length.

The three-stage polarization maintaining fiber amplifier is used to gradually increase the average power of the seed source from about 10mW to 15W, and to control the nonlinear growth process in the fiber to suppress the spectral spreading to ensure the subsequent high frequency doubling efficiency.

The electro-optical switch is used to chop the pulse into a pulse train with adjustable macro pulse width. The pulse train is further amplified by a solid-state amplifier and is required to guarantee power and energy fluctuations within 1%.

The amplified picosecond pulse train is frequency doubled by LBO crystal to 532nm, and then quadrupled by BBO crystal to 266nm deep ultraviolet light, with an efficiency of better than 10% from the fundamental frequency to the quadruple frequency. The output light after quadrupling frequency is output after being beam-expanded and shaped, and then imported into the photocathode cavity and focused on the photocathode material.

In order to achieve a stable pulse output, GZTECH has specially customized and developed a high-stability electronic control system based on its accumulated electronic control technology on MOPA pulsed lasers, including FPGA-based high-speed master control, low-noise pump constant current drive, high-precision crystal temperature control and high-bandwidth frequency-locked closed-loop electronics.

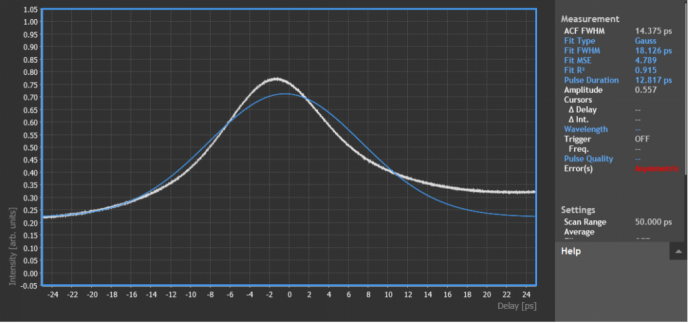

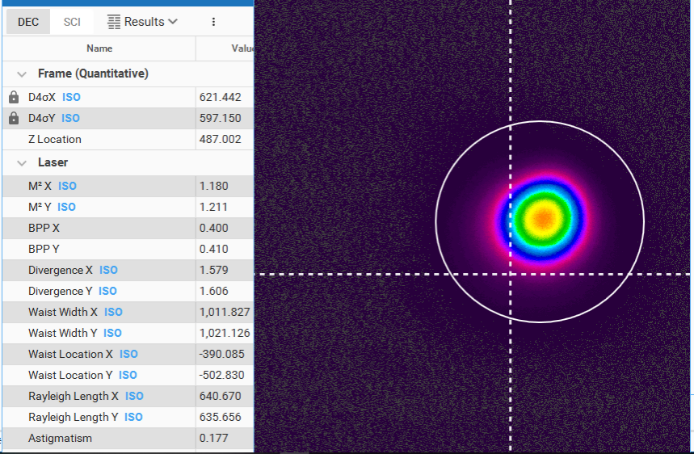

After one year of development and debugging work, the deep ultraviolet laser source finally delivered has achieved good optical indicators, as shown in the figure below. And the test work has been successfully completed.

(a) Picosecond pulse autocorrelation measurement curve

(b) Phase noise spectrum after frequency locking

(c) Beam quality of 266nm laser

GZTECH is a leading supplier of advanced industrial laser products for precision manufacturing. Welcome to send us samples for testing, we are ready to provide solutions for all kinds of your needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.