Cutting

Marking

Drilling

Welding

Cutting

Laser cutting is to use of a focused high-power density laser beam to irradiate the workpiece so that the irradiated material can quickly melt, vaporize, ablate or reach the ignition point. At the same time, with the help of the high-speed airflow coaxial with the beam, the molten material can be blown away, so as to cut the workpiece. GZTECH MOPA pulsed fiber lasers have a small laser spot, high energy density and fast cutting speed, high peak power, low average power, various pulse width and waveform options, and can easily realize the precision cutting of 3C 5G thin metal brittle and transparent material.

Marking

Laser marking technology is one of the application fields of laser processing. Laser marking is a marking method that uses a high-energy density laser to locally irradiate the workpiece to vaporize the surface material or change the color of the chemical reaction, so as to leave a permanent mark. Laser marking can print all kinds of characters, symbols, and patterns, and the character size can range from millimeters to microns, which is of special significance to the anti-counterfeiting of products.

3C products are often used high-gloss mirror LOGO, and the exquisite and bright mirror LOGO can easily highlight the brand's charm. GZTECH high-quality MOPA GMZ series pulsed fiber lasers with high beam quality<1.3, can mark the mirror LOGO at the designated position of the product, without the need for traditional rough grinding, fine polishing, cutting, inlaying and other processes, the operation is simple, and the LOGO design is flexible.

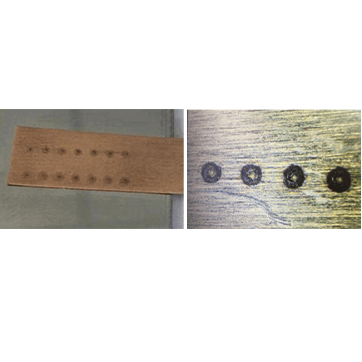

Drilling

Laser drilling is an early practical laser processing technology, and it is also one of the main application fields of laser processing. The laser beam is highly concentrated in space and time. By focusing with the lens, the spot diameter can be reduced to the micron level, so as to obtain the laser power density of 105-1015W / cm2. GZTECH has newly launched a high beam quality, high peak power adjustable pulse width GT series laser for glass punching, with high efficiency and good effect.

Welding

Laser welding is an efficient and precise welding method using a high-energy density laser beam as a heat source. Laser welding is one of the important aspects of the application of laser material processing technology. GZTECH MOPA pulsed fiber lasers by controlling the parameters such as laser pulse width, energy, peak power, and repetition frequency, can be used for 3C 5G battery soldering in PCBs, housings, shielding covers, USB connectors, conductive patches, etc.

GZTECH nanosecond welding is a precision welding process with high peak power which is especially conducive to the welding of high-reflection and high-melting point materials. And the single pulse energy is low, the single point heat is small, especially suitable for the welding of thin metal materials, and the welding deformation and residual thermal stress are small. In addition, the pulse energy has good stability, and the pad is composed of multiple solder joints. GZTECH nanosecond MOPA pulsed laser adopts an air-cooled all-fiber structure, which is compact and easy to maintain.