Welcome:GZTECH

Welcome:GZTECH

Stainless steel materials have excellent corrosion resistance, wear resistance, toughness, craftsmanship, non-toxicity and clean decorative properties, and have been widely used in building materials, kitchenware, bathrooms, automobiles, decoration, arts and crafts and so on. Stainless steel products have become indispensable materials in people's daily life. With the continuous improvement of people's living standards, people's pursuit of products is not only limited to its functions, but also more and more demands have been put forward to the added value of products such as appearance, artistic temperament, etc.

Because the natural color of stainless steel is silvery white, it gives people a sense of monotony and indifference. Inspired by pattern decoration, people began to pursue different colors on stainless steel, giving people a warm and soft feeling, and improving its added value. The colored stainless steel not only maintains all its original characteristics, but also many properties have been significantly improved compared with the original performance, such as chemical resistance, anti-aging properties. Colored stainless steel not only reflects its artistic side, but also more in line with people's pursuit of products.

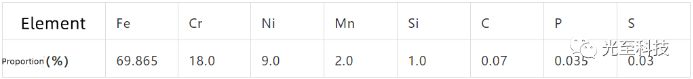

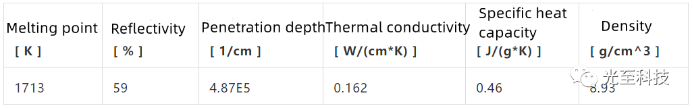

304 stainless steel is the most commonly used material in our daily life, as shown in Figure 1 and Figure 2, below are the main components and physical parameters of 304 stainless steel.

According to the widely used coloring technology of stainless steel, stainless steel coloring can be roughly divided into three categories: chemical coloring method, electrochemical coloring method and laser marking method. The first two categories are traditional coloring technology, and this post mainly introduces the principle and application of MOPA laser marking method.

For chemical and electrochemical coloring methods, due to the large use of chemical reagents, the proportion of the oxidizing liquid in the coloring process is very strict. The oxidation process is not easy to control, and irritating or toxic gases are inevitably generated. With the strengthening of environmental protection policies of governments around the world and the enhancement of people's awareness of environmental protection, these two types of traditional stainless steel coloring technologies cannot be widely promoted.

Under the action of laser heat, the surface of stainless steel produces colored oxides or a layer of colorless and transparent oxide film, which presents various colors due to the thin film interference effect of light. The color effect produced by stainless steel is mainly due to the interference effect of the film.

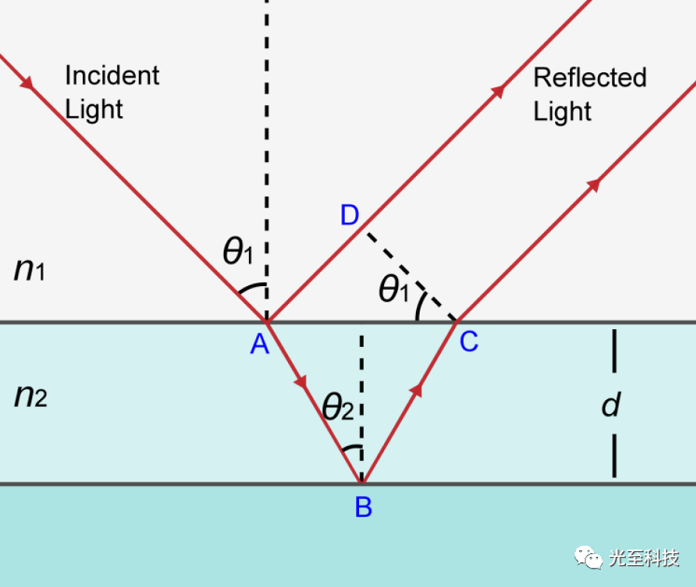

The pulsed laser beam acts on the surface of stainless steel, generating a layer (several hundred nanometers) of translucent oxide film on the surface of the metal. When the light enters the oxide film at a certain angle α, part of the light is reflected at the contact surface between the air and the oxide layer to form direct reflection light, and the other part of the light is refracted into the translucent oxide layer and then refracted into the air to form refracted light, forming interference with the original reflected light. Due to this interference phenomenon of light, some wavelengths of light are strengthened, and some are canceled, resulting in different color effects.

Compared with traditional coloring methods, MOPA laser coloring has many advantages.

(1) Non-contact processing, no consumables, no need to remove materials, not easy to wipe, high security;

(2) No chemical coloring, environmental protection and pollution-free, avoiding the production of toxic and harmful substances;

(3) Simple process, easy operation, high value-added products, mark any color patterns and text.

1. Mark color LOGO

2. Mark red metal pendant

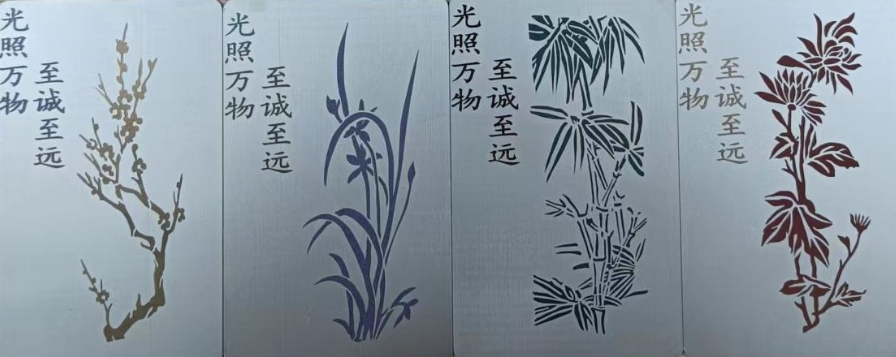

3. Mark crafts

For more information about MOPA laser, please kindly contact us directly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.