Welcome:GZTECH

Welcome:GZTECH

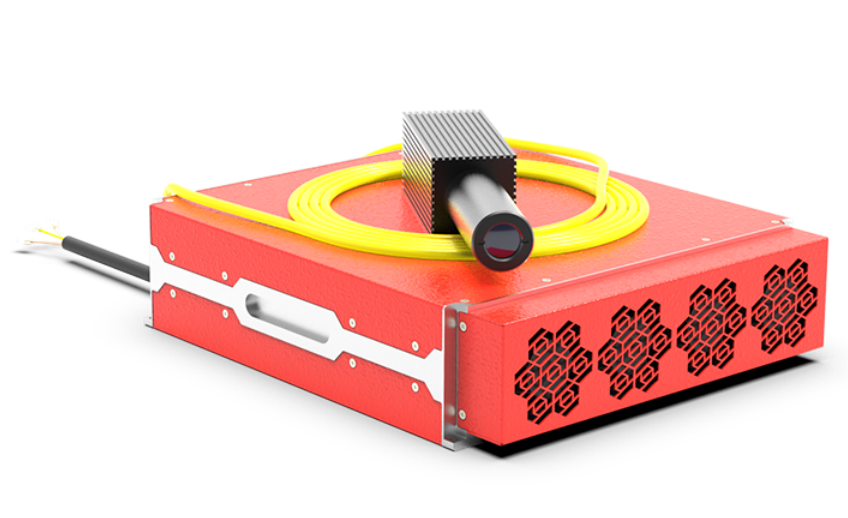

(1) After unpacking the MOPA fiber laser, please check whether the accessories of the fiber laser are complete and whether it is damaged (during transportation) according to the configuration list in the box.

(2) Before using the MOPA fiber laser, please make sure that the voltage of the power supply of the fiber laser is normal. The wiring of the laser power supply can be carried out according to the identification of the power cord and the instruction manual of the corresponding fiber laser. The wrong wiring method may cause damage to the fiber laser.

(3) Before using the fiber laser, please remove the dust cap from the isolator.

(4) After the fiber laser is powered on, please take protective measures to avoid direct contact of the eyes or skin with the laser, so as not to cause harm to the body.

(5) If the fiber laser is faulty, please contact our after-sales staff. Do not open the cover at will. If the laser label is torn or damaged, our company will not provide the warranty.

(1) For the connection of the laser power cables, please refer to the corresponding laser instruction manual or our company's laser wiring instructions for correct wiring.

(2) DB25 serial port cable connection, communication between external software and fiber laser, use external software (for example JCZ software) to control the laser emit light. For the specific interface definition of DB25 signal line, please refer to the laser instruction manual.

(3) DB9 serial port cable connection, our internal software (GUI software) communicates with the laser. Our internal software controls the laser emit light. Generally, after controlling the laser with the external control software, the DB9 serial port cable does not need to be connected. For the interface definition of the DB9 serial port cable, please refer to the laser instruction manual.

(1) Serial port cable driver installation, that is, USB to RS232 driver installation. For the specific installation method, please refer to the laser instruction manual for installation.

(2) GUI software installation. For the specific installation method, please refer to the laser instruction manual and install it.

Remarks: GUI software is our internal software to control the laser emit light. Generally, after the external software controls the laser's light output normally, you don’t need to install or connect this software.

|

Checklist of common problems with fiber lasers |

||

|

Serial No. |

Abnormal situation |

Troubleshooting method |

|

1 |

The fan does not rotate after the laser is powered on |

1. Check whether the power connection is normal. |

|

2. Replace the power supply. |

||

|

2 |

Abnormal sound of laser |

Ensure that it is the laser fan that is rattling and not other equipment. |

|

||

|

||

|

3 |

The laser does not emit light |

1. Please ensure that the laser fan is normal and the optical path is not blocked. |

|

2. Please make sure the hardware connection is normal, DB9 or DB25 connection is normal |

||

|

3. Please make sure the input voltage is normal. |

||

|

4. Please confirm that the software settings are normal. Marking machine select "Fiber". |

||

|

5. Check whether the software alarms. |

||

|

6. Please connect our company's "GUI" software to control the laser to emit light. If there is no light, an alarm message will be displayed. |

||

|

4 |

Laser power is low |

1. Please check whether the laser parameters are set normally. |

|

2. Please check whether the laser power supply voltage is normal. |

||

|

3. Please check if the power meter is testing normally. |

||

|

4. Check whether the laser output head is contamination. |

||

|

5. Use our company's "GUI" software to control the laser output and test the power. |

||

|

5 |

Abnormal light spot |

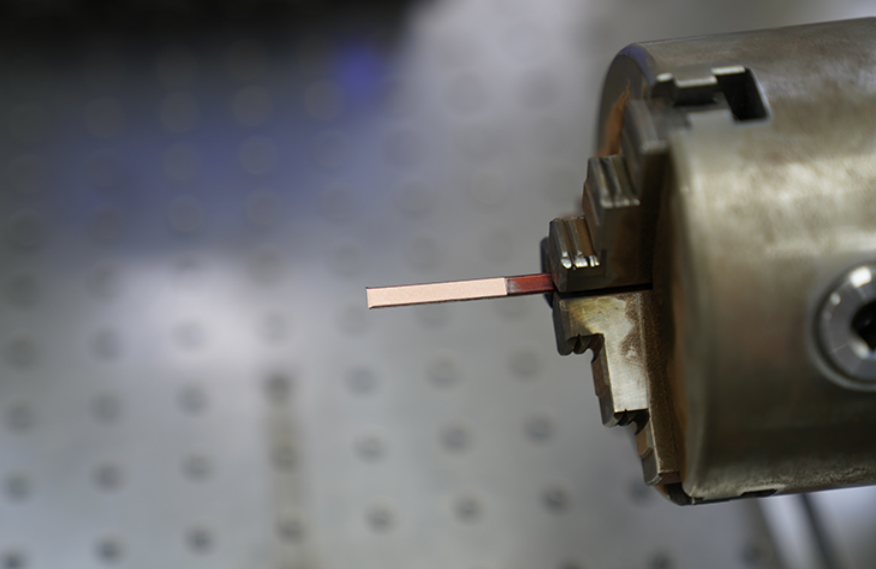

1. When turned off, observe whether the lens of the laser output head is clean and free of damage. |

|

2. Check whether the lens of the laser equipment is normal |

||

|

6 |

Marking ability has weakened |

1. Determine whether the laser parameters are suitable. It is recommended to use 200ns, reduce the power frequency point |

|

2. Check the status of the marking machine, adjust the lifting rod, check whether the light spot is stuck, whether the output light spot is a circular spot, and check whether the galvanometer, field-lens, and red light beam combiner are contaminated. |

||

|

3. Check whether the laser output power is normal. |

||

|

7 |

Laser parameters are not adjustable |

1. Check whether the model is a parameter-adjustable model. |

|

2. Use our company's GUI software to control. If it can be controlled, please check whether the DB25 cable is normal. |

||

|

3. Check if the DB25 cable is normal, replace the DB25 cable. |

||

|

4. If the above method cannot solve the problem, please contact the technical staff of our company. |

||

|

8 |

There is no "pulse width" adjustment option in the marking machine software |

1. Please select the correct control mode, select "Fiber" and "IPG_YLPM" mode. |

|

2. Please make sure this model is adjustable. |

||

If the above methods still cannot solve the problem, please contact our after-sales staff!

By continuing to use the site you agree to our privacy policy Terms and Conditions.