Welcome:GZTECH

Welcome:GZTECH

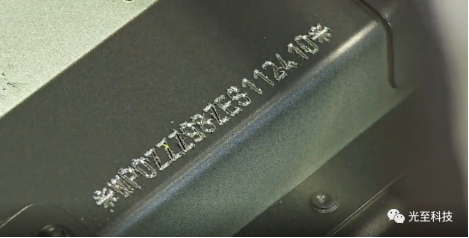

According to the regulations of GB7258, a motor vehicle must have a unique Vehicle Identification Number (VIN code for short). The ASE standard stipulates that the VIN code is composed of 17 characters, which includes information such as vehicle manufacturer, model year, model, body form and code, engine code and assembly location. Through the VIN code of a car, you can get the history report of the car and trace the relevant information,and it is equivalent to the ID number of each car. Therefore, the production of the VIN code is very important and must meet the GB16735 standard. The most important indicators are that the height of each character is greater than 7mm, the depth is greater than 0.3mm, and the range of engraving plane area should not be less than 20mmx130mm. After spraying, clear rubbing can be performed.

The traditional VIN code engraving generally adopts mechanical or pneumatic engraving methods, which is prone to the problem of uneven depth and failure to meet the depth requirements, thus affecting the vehicle factory inspection. In addition, traditional mechanical or pneumatic engraving belongs to contact engraving. The marking needle is easy to wear and needs to be replaced frequently, and high-strength steel engraving cannot be realized. Therefore, the laser processing method has gradually begun to be applied in the vehicle VIN code engraving due to its advantages of fast efficiency, long life, non-contact processing and no consumables.

Engraving effect of traditional VIN code

When the domestic high-power pulse laser technology has not yet matured, the general laser engraving uses pulse lasers with a power of less than 100W, and mainly uses the method of filling multiple engravings for deep engraving. This method works well but has a low efficiency. It usually takes tens of minutes for the engraving requirements of the VIN code, which is difficult to meet the efficiency requirements of tens of seconds for main engine factories.

In the recent two years, there has been a single-line engraving method using QCW single-mode lasers, and the depth and efficiency can meet customer requirements. However, because of the low frequency of QCW and the large energy of single pulses, the sparks are very large during the engraving process, and the bottom of the field mirror is very easy to be covered with metal slag. If the field mirror protector cannot be replaced every two hours, it is difficult to ensure long-term stable use. However, the main engine factory for VIN code engraving requirements of high efficiency, good effect, high equipment stability, field mirror protection mirror consumption will be an astronomical figure, which is not suitable for industrial production.

For QCW engraving method, laser engraving of VIN code can be achieved industrially as long as the impact of sparks splash on the field mirror is reduced in engraving. According to the characteristics of QCW single-mode laser, if the beam quality is guaranteed, the pulse laser power and repetition rate are increased, and the pulse width is reduced to ensure a certain peak power, then it is possible to achieve laser engraving of VIN code fast and well.

In order to achieve good effect and meet the needs of customers in a timely manner, GZTECH actively organizes R&D and process teams, and at the same time cooperates with well-known equipment integrators in the automotive industry. After many times of process development and verification, GZTECH finally achieved fast and good effects for engraving VIN codes with YFPN-500-GM lasers, and delivered several sets of equipment to customers, which have been in stable production for nearly a year now.

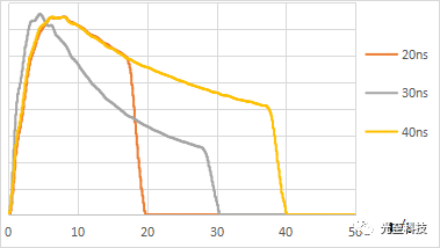

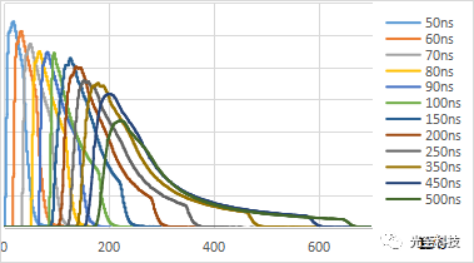

YFPN-500-GM is the first high-power single-mode pulsed fiber laser launched in China based on MOPA technology. It has an average power of up to 500W, a peak power of 15kW, M²<1.8 high beam quality, 10ns~500ns pulse width adjustable, 4000kHz high repetition rate, 5-meter optical fiber output and many other advantages.

YFPN-500-GM

Pulse Width Waveform

YFPN-500-GM with 254 field mirrors is used for VIN code engraving, and the engraving area can be 150*150mm to meet the requirements of VIN code. With a single line and dithering method, using the parameters of narrow pulse width and high frequency, the sparks will be controllable during the engraving process and will not splash to the lower surface of the field mirror, and the engraving of 17 characters plus 2 cut-off characters with a depth of more than 0.3mm can be completed within 20 seconds. With less surface burrs, clearly visible characters, easy rubbing with rubbing paper, VIN code is clearly visible. In addition, the solution can also achieve the engraving needs of different materials such as carbon steel, stainless steel, and galvanized plate.

GZTECH is a high-tech company with the orientation of "serving advanced light source supplier of precision manufacturing".The company's main products are industrial pulse lasers, including infrared fiber MOPA, QCW, nanosecond fiber green laser, nanosecond high-power UV and fiber picosecond laser, etc. The company's related products have been widely recognized by customers and the market in lithium battery, photovoltaic, and hydrogen energy industries, hard and brittle material processing, surface marking and cleaning applications.

In order to meet the needs of various customers,our company has set up offices in Shenzhen, Suzhou, and Jinan with Wuhan headquarters as the center, and can provide customers with sampling services. Welcome all the customers to come to discuss the development of new laser technology with us!

If you need samples, you can follow the wechat official account of "GZTECH", submit the form and we will provide you with free sample services!

By continuing to use the site you agree to our privacy policy Terms and Conditions.