Welcome:GZTECH

Welcome:GZTECH

As consumer interest in smart home products increases, smart mirrors are beginning to gain recognition in the market and are gradually becoming a part of high-end home decoration. By 2024, well-known institutions estimate that the global smart mirror market will reach $4.35 billion. Smart mirror combines tradition and technology, personalized demand gradually rises, and will be further integrated into daily life.

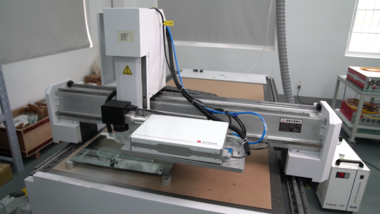

The production of smart mirror is inseparable from the mirror paint stripping, grinding and other processes, and the traditional mirror paint stripping, grinding process is difficult to meet the personalized customized needs of consumers, laser processing has flexible design without mask, high production efficiency, pollution-free environment and other advantages, will become the preferred way of smart mirror processing. The GT-Pro+ peak fiber laser launched by GZTECH can complete various processes such as mirror sanding, paint stripping, and hole punching at one time, and can also solve the problem of large-format production splicing through the equipment solution of galvanometer and shaft linkage.

The traditional mirror processing process is complex and cumbersome, which requires first covering, then engraving, then manually tearing the film, then removing paint, and finally sandblasting. Later, the laser gradually replaced the physical process, but it still required three steps to complete the processing needs. The peak value GT-Pro+ can be completed in only one step, reducing the process, saving labor, and no consumables, more environmentally friendly.

Laser processing is a high-precision, non-contact processing technology, which is not only simple to operate, but also can meet the complex and refined process requirements. GZTECH's GT-Pro+, with high peak power, Pp>200kW, equivalent to 20 times the conventional fiber pulse, good beam quality, M2<1.3, its advantages in smart mirror processing are mainly reflected in the following aspects:

The GT-Pro+ provides peak laser pulses that release extremely high energy in a very short period of time, rapid processing, and can be automated to achieve mass production.

The GT-Pro+ achieves fine processing of the smart mirror by precisely controlling the energy of each laser pulse and keeping the focus spot small. While meeting the complex processing requirements, it avoids damaging the sensitive structures and components inside the smart mirror.

GT-Pro+ has high peak value, short pulse duration and small heat affected zone, which can reduce thermal damage to other parts of the smart mirror during processing, and non-contact processing will not cause mechanical pressure or wear on the surface of the smart mirror, and the processing effect is better.

Any pattern processing without stencil, computer editing, on the go, very suitable for individual needs.

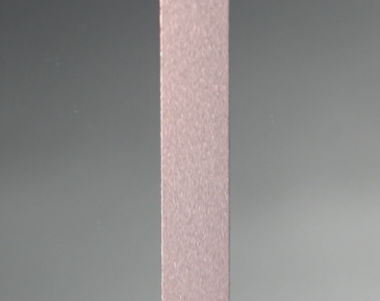

As shown in the figure, GZTECH's GT-Pro+ uses the parameters of 85% power, 120kHz frequency, 30ns pulse width and 6000mm/s to sand the mirror. The sanding effect has a fine texture, neat edges, no marks, and uniform and soft light transmission.

Sanding details, sanding operation

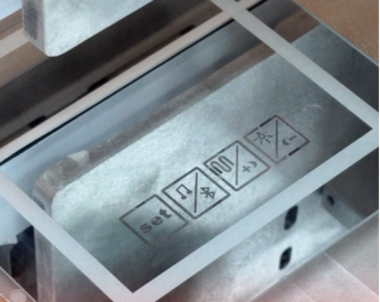

We used GT-Pro+ to remove paint from touch keys. The frequency was 120kHz, the power was 85%, the pulse width was 30ns, and the average time for a single key was 3s. The peeling effect was clean without residue and the mirror was not damaged.

Peeling details, peeling operation

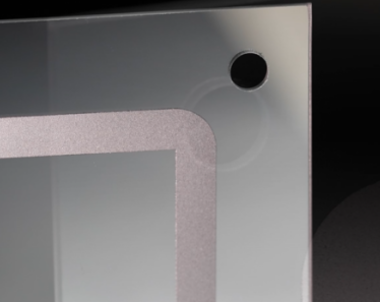

As shown in the figure, a 2mm hole is punched in a mirror with a thickness of 2mm. The laser power is 90%, the frequency is 30kHz, and the pulse width is 20ns. The damage to the paint layer after completion is less than 200μm.

Punch effect picture

Edge damage

If you need to do proofing tests, contact us for free proofing, you can see the effect on site!

GT-Pro+ is not only excellent in the field of smart mirror processing, but also widely used in the drilling, coating, peeling, marking of various glass materials such as float glass, optical glass, glass-ceramics, conventional calcium-sodium glass, architectural glass, high-borosilicate glass, etc., to meet the processing needs of a variety of materials. GZTECH always adheres to the development vision of "serving advanced light source supplier of precision manufacturing", and is committed to providing efficient and intelligent solutions for various enterprise users. If you want to have a deeper understanding of our products, please pay attention to us!

By continuing to use the site you agree to our privacy policy Terms and Conditions.