Welcome:GZTECH

Welcome:GZTECH

Glass, as an amorphous inorganic non-metallic material, is transparent and smooth, widely used in the production of various items and decorative crafts such as doors and windows. In modern daily life, production, and scientific fields, glass has become an essential material. With the development of society and the growing awareness of environmental protection, there are higher demands for frosting glass products. Nanosecond UV laser processing of glass frosting offers advantages such as controllable texture, high efficiency, stable operation, and simple procedures. It is expected to gradually replace or supplement traditional processing methods.

|

|

|

|

Glass Frosting Overall Image |

3C Marking Image |

|

Processing Method |

Laser Frosting |

High-Pressure Sandblasting |

Hydrofluoric Acid Chemical Etching Frosting |

|

Cost |

Lower cost, initial equipment investment, minimal ongoing costs |

Higher cost, expensive purchase of abrasive materials |

Moderate cost |

|

Operation |

Simple operation, automated process through software settings |

Filling abrasive materials, simple process with high-pressure spray gun |

Hydrofluoric acid applied to glass surface, suitable for overall frosting, complex local frosting steps |

|

Safety |

High safety |

Safety hazards exist |

High danger, risk of bodily harm |

Glass has high chemical stability, while the chemical agents used in chemical etching frosting have certain corrosive properties, posing significant risks to the environment, equipment, and operators. Sandblasting/grinding frosting reduces production yield, slows down efficiency, requires strict process control, and can contribute to environmental pollution. The use of nanosecond solid-state UV lasers for glass surface frosting effectively addresses the pain points of traditional processing, offering rapid efficiency, no pollution, environmental friendliness, and low consumption, thereby driving innovation in glass processing technology and realizing economic value.

The nanosecond solid-state UV laser operates at a wavelength of 355nm, with high absorption of UV laser by glass. Due to the small focused spot and high energy density, UV processing for glass frosting achieves finer results.

|

Testing Platform Information |

|

|

Laser Source |

15w and 30w |

|

Beam Expander |

15w(355 10X) 30w(355 8X) Output spot 5mm |

|

Field Lens |

F=254 |

|

Scanning Mirror |

SCANLAB 10mm |

|

Control Card |

Golden Orange Second Generation |

Due to the inherent brittleness of glass, improper control of laser energy parameters can lead to the expansion of microcracks, thermal cracking, or severe edge collapse on the glass surface. To achieve varying levels of opacity, light transmittance, roughness, and aesthetic surface effects, it is imperative to carefully select and adjust the appropriate laser processing parameters.

|

Laser Frosting Process Parameters |

||

|

Processing Parameters |

15W |

30W |

|

Marking Speed (mm/s) |

700 |

1300 |

|

Frequency (kHz) |

60 |

80 |

|

Pulse Width (us) |

2 |

2 |

|

Fill Type |

Arch-shaped |

Arch-shaped |

|

Fill Spacing (mm) |

0.07 |

0.08 |

|

|

|

|

Efficiency Comparison Image |

Surface Roughness Testing Image |

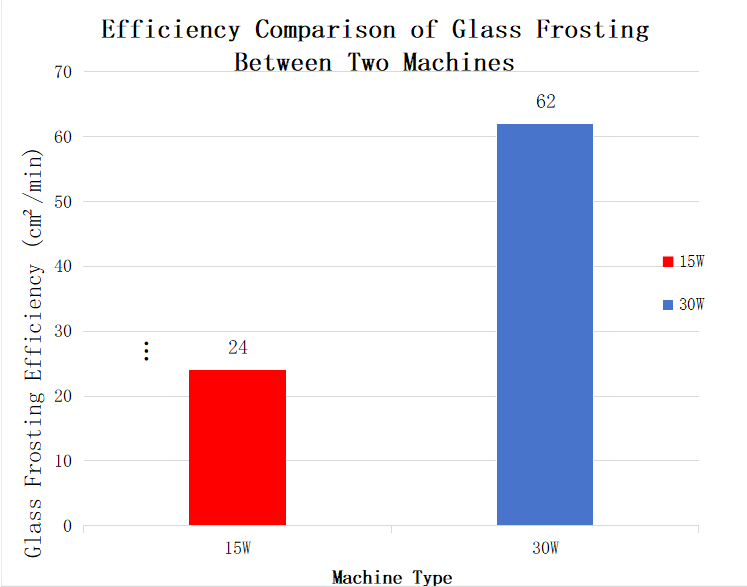

With consistent frosting effects, we compared the efficiency of frosting using 15W and 30W lasers. The results show that the higher power laser achieves approximately 2.5 times higher efficiency than the 15W laser. The 30W UV high-power laser, with its greater single pulse energy, improves output frequency and processing speed, making it more efficient and cost-effective in glass frosting applications.

|

|

|

30W UV Laser Appearance Image |

|

No. |

Parameter Name |

Parameter Value |

Unit |

|

1 |

Center Wavelength |

355 |

nm |

|

2 |

Maximum Pulse Energy |

>750 (@40kHz) |

μJ |

|

3 |

Output Power |

>30 (@40kHz) |

W |

|

4 |

Frequency Adjustment Range |

30~200 |

kHz |

|

5 |

Pulse Width |

10~40(15±2ns@40kHz) |

ns |

|

6 |

Output Power Stability |

< 3% RMS |

|

|

7 |

Pulse Stability |

<3% RMS |

|

|

8 |

Beam Quality M2 |

< 1.3 |

|

|

9 |

Beam Mode |

TEM00 |

|

|

10 |

Beam Circular Degree |

>90 |

% |

|

11 |

Polarization Direction |

Horizontal |

|

|

12 |

Spot Diameter (6x Beam Expander) |

5±0.5 |

mm |

|

13 |

Divergence Angle |

<2 |

mrad |

|

14 |

Pointing Stability (8h) |

<25 |

urad/°C |

|

15 |

Laser Size |

480210135.8 |

mm³ |

GZTECH is an advanced laser source supplier focused on serving precision manufacturing. With headquarters in Wuhan and five offices nationwide, including branches in Shenzhen and Suzhou, we provide comprehensive services to meet diverse customer needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.