Welcome:GZTECH

Welcome:GZTECH

Glass is an amorphous inorganic non-metallic material that is transparent and smooth. It can be used to make objects, as well as to decorate doors and windows and other craft works. At present, glass has become an important material in modern daily life, production, and scientific and technological fields. With the development of society and the enhancement of environmental awareness, people have put forward higher requirements for the texturing of glass products. UV laser processing of glass texturing has advantages such as controllable texture, high efficiency and stability, convenient equipment operation, and simple process. It will gradually replace or replace traditional processing methods.

Overall glass texture diagram

3C marking diagram

Glass has high chemical stability, and the chemical reagents used for chemical etching and texturing have a certain degree of chemical corrosiveness, which poses significant harm to the environment, equipment, and operators; Sandblasting/matte roughening reduces production yield, efficiency, strict process control, and can also cause certain environmental pollution. The use of nanosecond solid ultraviolet laser for surface texturing treatment of glass can effectively solve the pain points of traditional processing technology, with the characteristics of fast, efficient, pollution-free, environmentally friendly, and low loss. It can promote technological innovation in glass processing and achieve a certain economic value.

The wavelength range of nanosecond solid-state ultraviolet is 355nm, and the glass has a high absorption rate for ultraviolet laser. Due to the small focusing spot and high energy density, the glass texture is more delicate when processed by ultraviolet.

Due to the brittle nature of glass, improper control of laser energy parameters can easily lead to microcrack propagation, thermal cracking, or severe surface edge collapse of glass. In order to pursue different haze, transmittance, roughness, and surface aesthetic effects, it is necessary to select and adjust appropriate laser process parameters

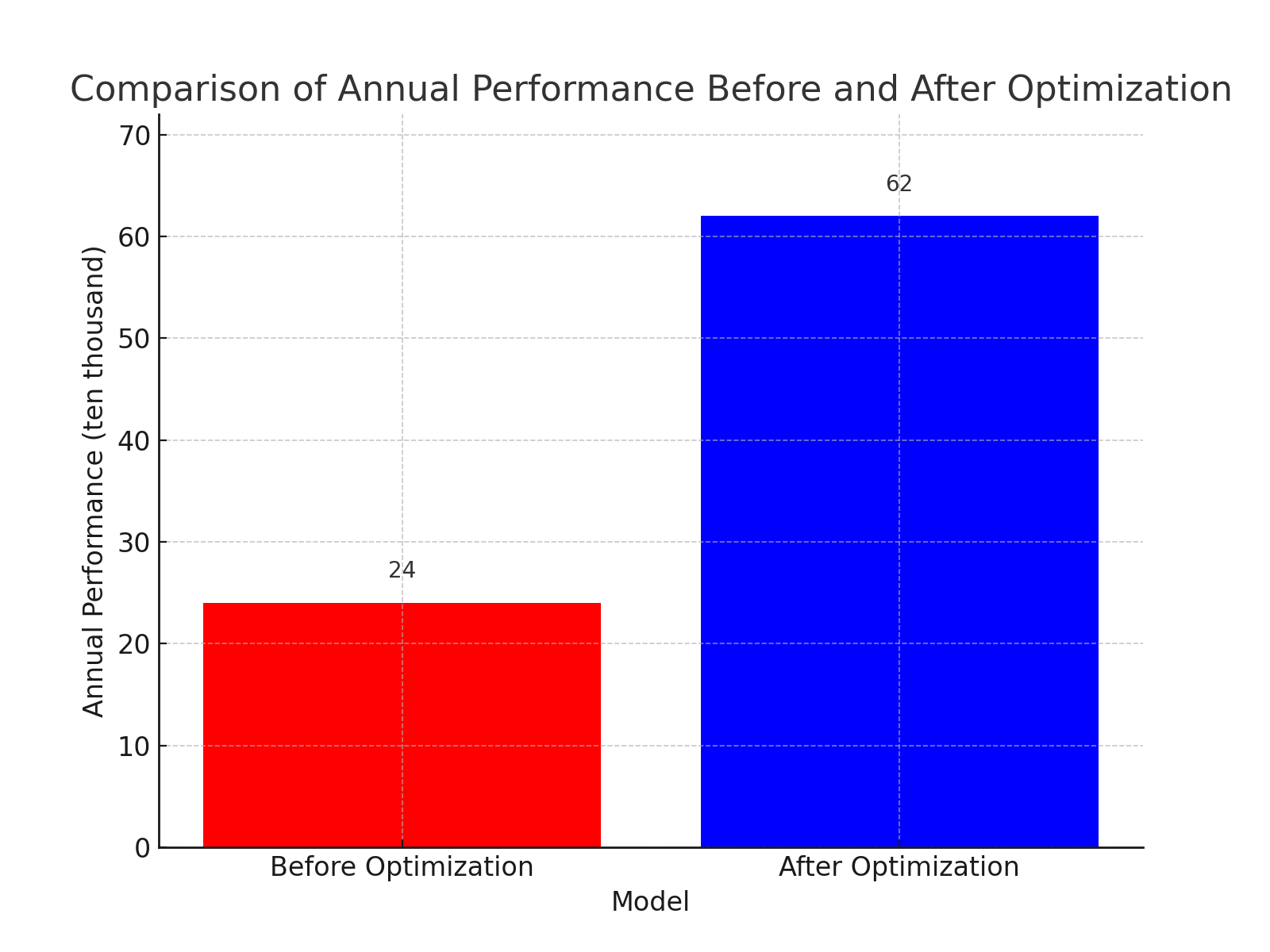

We compared the texturing efficiency of two different power lasers, 15W and 30W, when the texturing effect was consistent. According to the test results, the texturing efficiency of the high-power laser was higher. The efficiency of the 30W laser was 158% higher than that of the 15W laser, and the 30W laser has a larger single pulse energy. During processing, the output frequency can be increased, which in turn increases the processing speed, Therefore, it is more efficient and cost-effective in the application of glass texturing.

Efficiency comparison chart

Roughness test image

Microscopic image of the texturing effect

30W UV appearance diagram

Design water cooling circuits for each hot spot and adopt the optimal cooling scheme to achieve high-precision cooling.

Special doping is applied to conventional crystals to enhance the thermal conductivity of gain crystals and effectively control crystal thermal effects.

Design the optimal structural scheme for thermal stability through multiple rounds of thermal simulation and practice.

A reasonable coupling scheme and cavity design ensure stable power output of the product。

By continuing to use the site you agree to our privacy policy Terms and Conditions.