Welcome:GZTECH

Welcome:GZTECH

In our journey through the intricate world of fiber lasers, we've discussed fundamental physical concepts, spatial and temporal domain quantities, and the components that make up these advanced laser systems. In this final installment, we'll delve into some key components and operational modes that play a pivotal role in the functionality and versatility of fiber lasers.

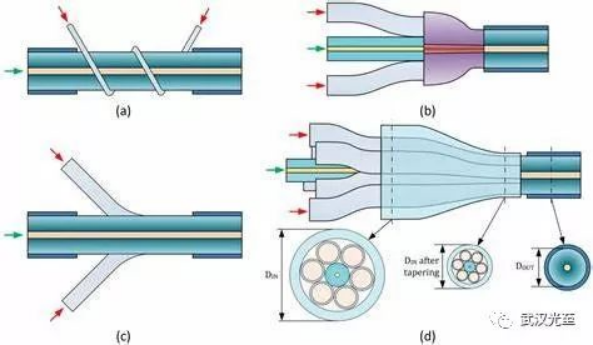

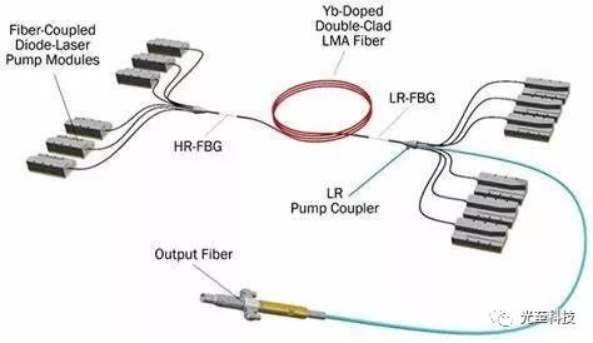

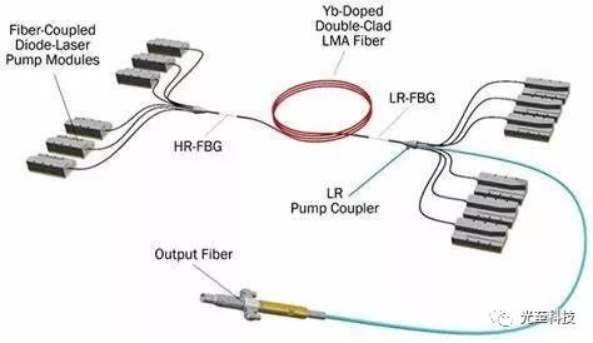

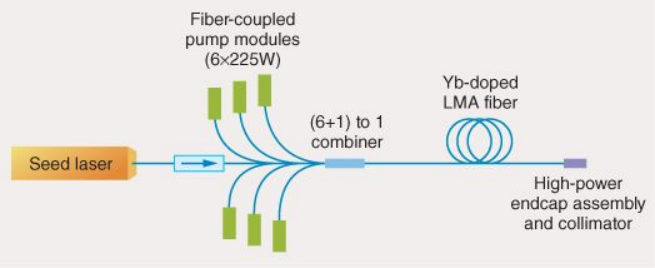

Fiber lasers often rely on semiconductor lasers with emission wavelengths of 915nm or 976nm as pump sources. These pump lasers generate high-power pump output by combining the output of multiple semiconductor chips, and this pump light is coupled into a multimode optical fiber. The process involves using a Multimode Pump Combiner (MPC), which fuses multiple pump sources into a single output fiber. The resulting fiber typically has a larger core diameter and numerical aperture than the input fibers. This efficient coupling allows for pump power delivery with high optical efficiency, typically ranging from 90% to 98%.

The Pump Signal Combiner (PSC) is another crucial passive optical fiber component. It combines the central signal fiber with surrounding pump fibers using a fused-taper process. The PSC must not only efficiently couple pump light but also ensure minimal signal insertion loss and preserve the beam quality. There are variations of PSCs, including end-pumping and side-pumping configurations, depending on their application within the laser system.

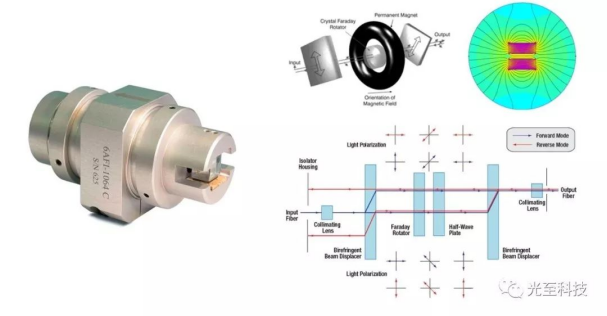

Optical isolators are devices that make use of the Faraday effect to allow light to pass in only one direction. They are essential for protecting laser sources by preventing back-reflected light from interfering with the laser cavity. Optical isolators are available in both polarization-maintaining (PM) and non-PM configurations, offering varying degrees of isolation. High-quality isolators can achieve isolation levels of 30dB or more, ensuring minimal back-reflected power.

Inline Optical Isolators are designed with input and output fibers on both sides, making them suitable for systems where space is limited. Collimated Optical Isolators, on the other hand, output light in a collimated beam format, making them ideal for applications like preventing back-reflected light from entering the laser source during material processing.

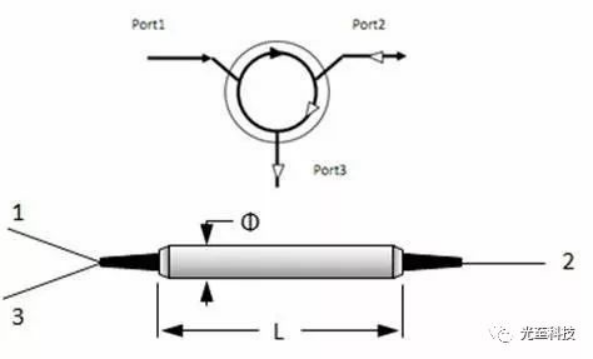

Circulators are three-port devices that guide light from one port to another in a circular fashion. They are often used in dual-path laser amplifiers or as part of grating stretcher-compressor systems. Circulators ensure unidirectional light propagation and are crucial for managing the optical path in complex laser systems.

Reflecting mirrors are comprised of optical fibers, collimating lenses, and high-reflectivity mirrors. They are used to redirect light within the laser system, such as in amplifiers or cavities. Some designs incorporate Faraday mirrors for polarization control or bandpass filters to select specific spectral components.

Continuous Wave Lasers operate in a continuous, stable output mode. They are commonly used in high-power laser systems. For instance, CW lasers below 300W may utilize air cooling, while higher-power models typically require water cooling. CW Laser Resonators, such as those found in fiber lasers, consist of gain fiber, pump sources, and cavity mirrors that enable continuous laser oscillation and output.

Quasi-CW lasers operate with high-duty cycle pulsed modes, typically with pulse widths in the microsecond to millisecond range. Nanosecond Pulsed Lasers have pulse durations in the nanosecond range and find applications in materials processing, marking, and more.

Pulsed Q-Switched Fiber Lasers use a Q-switch within the laser cavity to generate high-energy, high-peak-power pulses with repetition rates typically in the range of 10kHz to 100kHz.

Ultrafast Pulsed Lasers produce extremely short pulses, often in the femtosecond to picosecond range. They are ideal for precision material processing due to their ability to minimize heat-affected zones.

Mode-Locked Pulsed Lasers use passive mechanisms like SESAM or NPR to generate ultra-short pulses in the picosecond or femtosecond range. These lasers have complex dynamics, and under specific conditions, they can produce soliton-like pulses.

Co-pumping and Counter-pumping refer to the direction in which pump light is applied relative to signal light propagation in fiber amplifiers. Co-pumping involves pump and signal light traveling in the same direction, while Counter-pumping has them traveling in opposite directions. Counter-pumping often yields lower ASE noise and reduced non-linear effects.

Single Pass Fiber Amplifiers amplify the signal light as it passes through the gain fiber once. Double Pass Fiber Amplifiers use an optical circulator to pass the signal through the gain fiber twice, increasing the overall gain and signal-to-noise ratio.

MOPA is a common laser configuration that separates the laser oscillator (seed source) and power amplification stages. This separation allows for better control over the seed source and efficient power scaling in the amplifier. It's widely used in pulsed laser systems.

ASE is the phenomenon where spontaneous emission from gain media is amplified, resulting in broadband noise. It becomes significant in pulsed lasers with low duty cycles, weaker seed sources, and high gain amplifiers.

In conclusion, comprehending these advanced components and operational modes is crucial to unlock the full potential of fiber lasers. GZTECH, our company, is at the forefront of these innovations, contributing to diverse fields such as materials processing and telecommunications. As the laser industry propels forward, new concepts and technologies will continue to emerge, augmenting the capabilities of these remarkable devices. Join us at GZTECH in shaping the future of laser technology.

By continuing to use the site you agree to our privacy policy Terms and Conditions.